Versatile and outstanding building material

Cross Laminated Timber (CLT) can be used for external and internal walls, intermediate ceilings and roof panels in conjunction with other building materials.

CLT layers are alternately cross-laminated from finger-jointed material with a moisture content of 12 ±2%, resulting in high load-bearing capacity in two directions.

The number of CLT layers is always odd – 3, 5, or 7 (except in some special cases – 9 layers).

The crossed layers create a locking effect that makes for very good dimensional stability in the event of changes in humidity and significantly reduces the negative effects of drying.

CLT has no architectural constraints, which means that more and more CLT is being used for building private houses, apartment buildings as well as industrial and commercial buildings.

The use of CLT in bridge building has become more and more popular. Its large format elements accelerate the construction process greatly. Fixings between panels are made quickly for screws, bolts, and pins and do not require extra drying time.

Features

- Suitable for wall, intermediate ceiling, and roof ceiling elements

- Large-size tiles available

- Very good fire resistance properties

- Building material with a positive CO2 balance

Advantages

- Great architectural design options

- Environmentally friendly building material

- It provides a healthy and cosy indoor environment

- Positive CO2 balance

- Short construction period

- Highly accurate dimensions thanks to CNC machining

- 16 times lighter than steel and five times lighter than concrete

- High fire resistance

- Can be combined with different materials

- Up to 10% more living space when using CLT

Areas of use

- Private dwellings and apartment buildings

- Public buildings

- Renovated buildings

- Bridges

- Hotels and restaurants

- Schools and kindergartens

- Offices and administrative buildings

- Industrial and commercial buildings

Technical information

| Maximum dimensions: | 3.6×15.1 m |

| Thickness of panels: | 60-350 mm |

| Number of layers: | 3, 5, 7 layers (9 layers in special cases) are possible |

| Thickness of layers: | 20, 30 või 40 mm |

| Wood species: | Spruce |

| Wood moisture content: | 12 % ± 2 % |

| Panel finishing: | Grooves and recesses can be milled into the panel surface for utility connections. Any necessary door and window openings can be cut into the panel |

| Panel width: | Panels up to 3.6 m wide can be machined using a CNC machine |

| Use: | Not recommended for use under class 3 conditions |

| Surface quality: | Since the panels are mainly used as in-structure elements, they are manufactured with a non-visual (NVI) quality |

| Combined quality: | With custom-made orders, it is possible to manufacture combined panels where one side is non-visible (NVI) and the other side is of visible (VI) quality or both sides are visible (VI) quality. |

| Strength class: | C24 in accordance with EN 338, C16 on inner layers if possible |

| Adhesive: | 1C polyurethane adhesives (PUR) in accordance with EN 15425 |

| Lateral shear strength: | 1.2 MPa and module G_90=65 MPa if the width of the cross layers is greater than 4 times the thickness. In other cases, the lateral shear strength is 0.7 MPa and G_90 = 50 MPa |

| The combustion rate: | 0.65 mm/min if joints between layers are up to 2 mm and 0.8 mm/min when the joints are 2-6 mm |

Surface quality

We manufacture CLT panels with different surface qualities to meet your needs and requirements. As standard, we produce CLT in two different qualities – visible and non-visible. Different surface qualities can be combined to suit your needs and interior design preferences. The choice of surface quality will depend on the subsequent use of the panel and this should be taken into account at the design stage.

Visible

Panels with visible surface quality are ideal for use as surfaces that are permanently on display if you would like to showcase the wooden structure and its natural properties, such as on interior walls inside office and residential buildings. The surface is polished.

Non-visible

Structural CLT elements produced with non-visible surface quality, i.e. with knots, resin pockets and changes in wood colour. These panels are appropriate for use in load-bearing structures that are generally covered with other materials.

Special treatment

In addition to grinding, we also offer brushed (milled) quality visible surfaces. Brushing gives wood a much more interesting and original appearance and enhances its structure. If desired, it is also possible to finish the panels with different finishing materials (oil, varnish, tinting, etc.).

Standard measurements

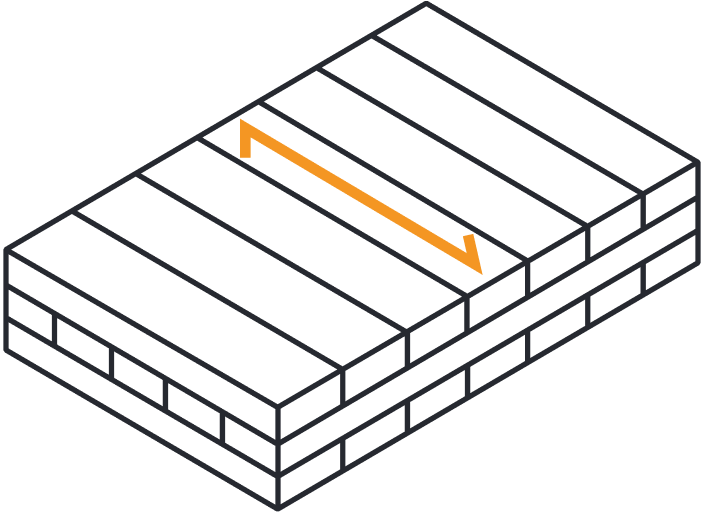

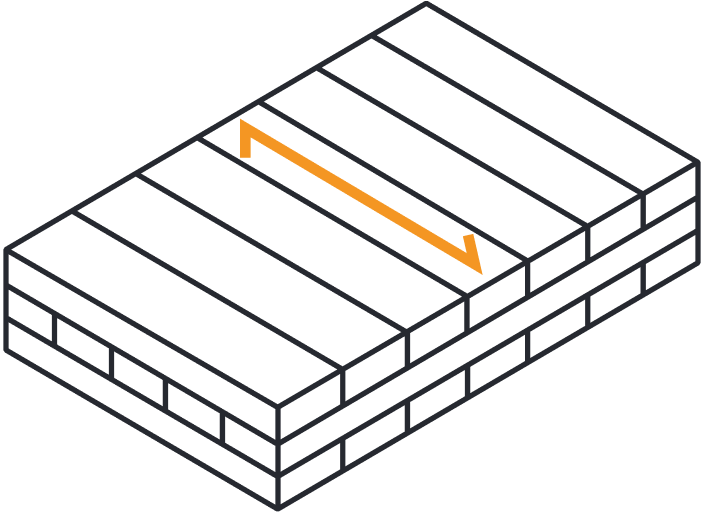

SP Panel / Wall panels

| Panel thickness mm | Layers | Layer layout | ||||

|---|---|---|---|---|---|---|

| C | L | C | L | C | ||

| 60 | 3 | 20 | 20 | 20 | ||

| 80 | 3 | 30 | 20 | 30 | ||

| 90 | 3 | 30 | 30 | 30 | ||

| 100 | 3 | 30 | 40 | 30 | ||

| 120 | 3 | 40 | 40 | 40 | ||

| 100 | 5 | 20 | 20 | 20 | 20 | 20 |

| 120 | 5 | 30 | 20 | 20 | 20 | 30 |

| 140 | 5 | 40 | 20 | 20 | 20 | 40 |

| 160 | 5 | 40 | 20 | 40 | 20 | 40 |

| 180 | 5 | 40 | 30 | 40 | 30 | 40 |

| 200 | 5 | 40 | 40 | 40 | 40 | 40 |

L- Lengthwise layers, C- Crosswise layers

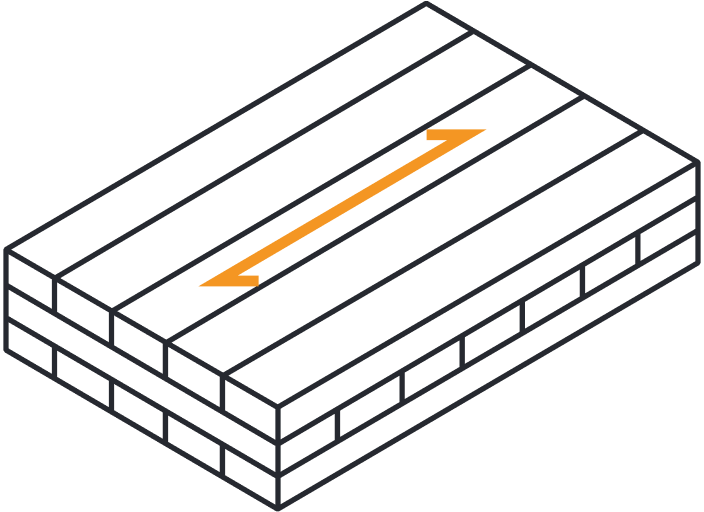

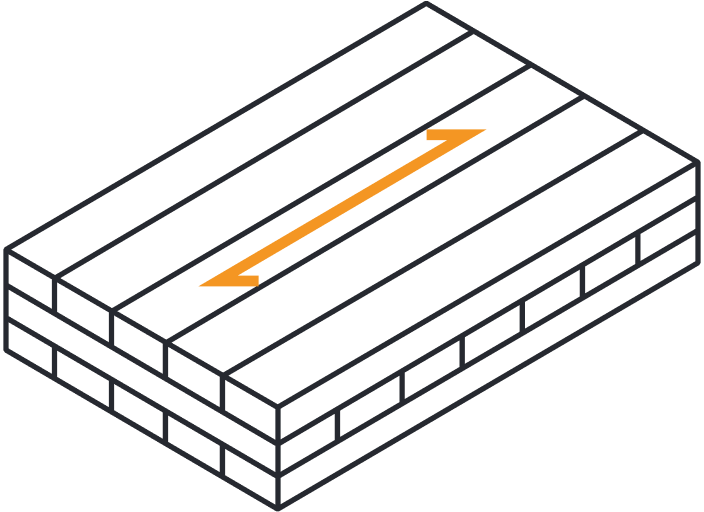

VL: KL Intermediate and roof ceiling panels

| Panel thickness mm | Layers | Layer layout | ||||||

|---|---|---|---|---|---|---|---|---|

| L | C | L | C | L | C | L | ||

| 60 | 3 | 20 | 20 | 20 | ||||

| 80 | 3 | 30 | 20 | 30 | ||||

| 90 | 3 | 30 | 30 | 30 | ||||

| 100 | 3 | 30 | 40 | 30 | ||||

| 120 | 3 | 40 | 40 | 40 | ||||

| 100 | 5 | 20 | 20 | 20 | 20 | 20 | ||

| 120 | 5 | 30 | 20 | 20 | 20 | 30 | ||

| 140 | 5 | 40 | 20 | 20 | 20 | 40 | ||

| 160 | 5 | 40 | 20 | 40 | 20 | 40 | ||

| 180 | 5 | 40 | 30 | 40 | 30 | 40 | ||

| 200 | 5 | 40 | 40 | 40 | 40 | 40 | ||

| 220 | 7 | 30 | 30 | 30 | 40 | 30 | 30 | 30 |

| 240 | 7 | 30 | 40 | 30 | 40 | 30 | 40 | 30 |

| 260 | 7 | 40 | 40 | 30 | 40 | 30 | 40 | 40 |

| 280 | 7 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

L- Lengthwise layers, C- Crosswise layers

Use the excellent properties of CLT in your project!

ARCWOOD is your reliable partner in implementing sustainable and efficient construction projects.