Leading manufacturer of timber structures in the Baltics

Peetri Puit is a family business that was founded in 2000 by Peeter and Aime Peedomaa. The company started as a small timber industry in Põlva County with just five employees. Today, it is one of the largest manufacturers of timber structures in the Baltics, operating under the brand name ARCWOOD.

We specialise in the production of CLT, glued laminated timber and finger-jointed structural timber. We design, manufacture and install innovative and sustainable construction solutions for public buildings, office buildings, residential and apartment buildings, industrial and commercial buildings, sports facilities and other buildings.

Your partner at every project stage

We will be your trusted and professional partner from design to installation. You can count on us to provide input, help determine the best solutions and put them into practice.

Our passion and expertise lies in delivering unique custom projects. Let us know your ideas and let us work together to devise a solution.

Quality in everything we do

We invest in quality and do not compromise. Our products are made with materials sourced from sustainably managed forests and are manufactured using cutting-edge technology in line with all current manufacturing and construction standards. Our agreements and promises bear the same quality mark as our products. You can rely on them.

Complex ideas turned into functional solutions

Mass timber has endless applications. If you work as an architect, let your imagination run wild, and we will make your ideas come true. We can manufacture glulam beams of any shape and up to 36 metres in length on CNC numerical control machines, with special emphasis on detail and precision.

Environmentally friendly solutions

We are proud to play our part in shaping architecture that stands out from the rest, while remaining thoroughly environmentally friendly.

We place great emphasis on sustainable management.

Our manufacturing complies with stringent quality and safety standards audited both in-house and by external international accreditation labs.

Flexibility and capacity to produce custom orders

Complete solutions from design to installation

High tech CNC technology

Certificates and compliance with standards

Timed deliveries: ARCWOOD knows the time

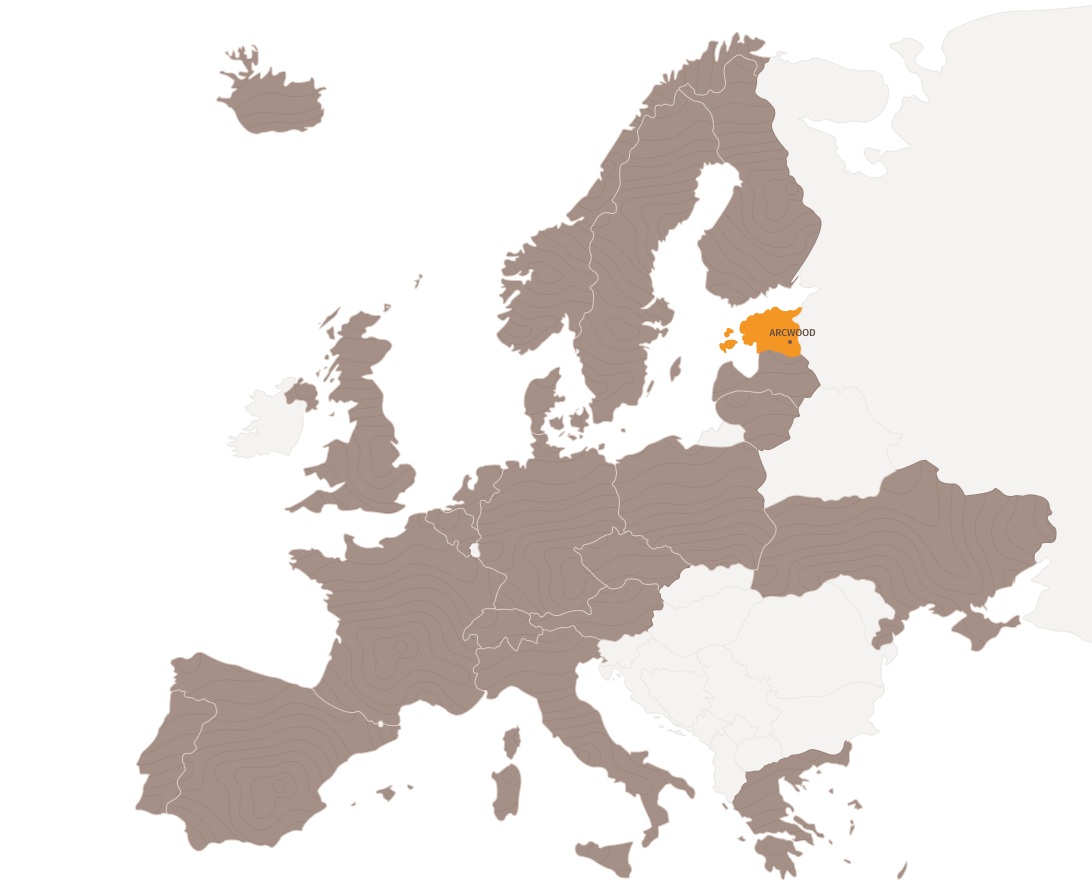

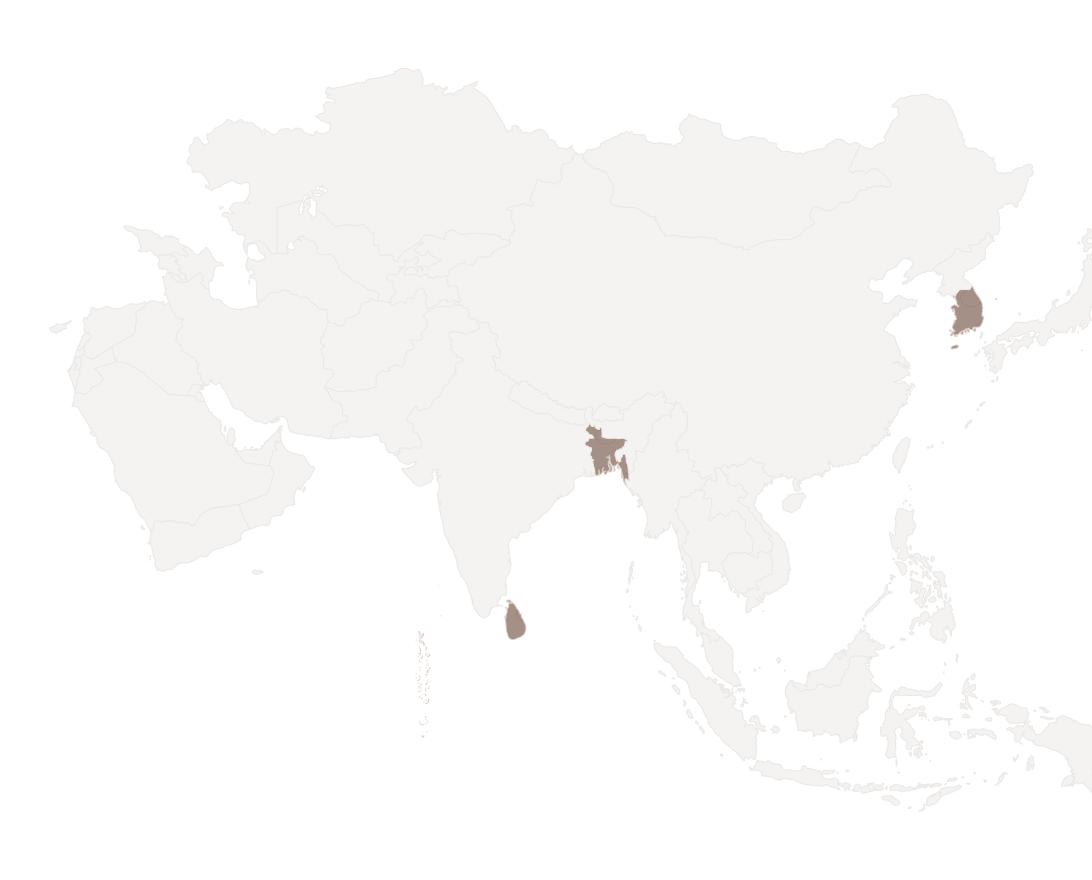

ARCWOOD products have also reached Europe and Asia

Our products have successfully established a presence in Europe and further afield in Asia, including the Maldives, South Korea, Bangladesh and Sri Lanka. This attests to our company’s ability to compete internationally.

- Arcwood production

- Where our products have reached

Awards

Estonian Entrepreneurship Awards 2022:

Family Enterprise

Prefab House of the Year 2019:

Best timber use

Prefab House of the Year 2019:

Best public building

Timber Building of the Year 2016:

Overall Winner

Wood – environmentally friendly and sustainable

We operate sustainably and offer this opportunity to our customers. Wood is the most eco-friendly building material, and its benefits are hard to compete with.